1-component foam technology with a wide range of applications

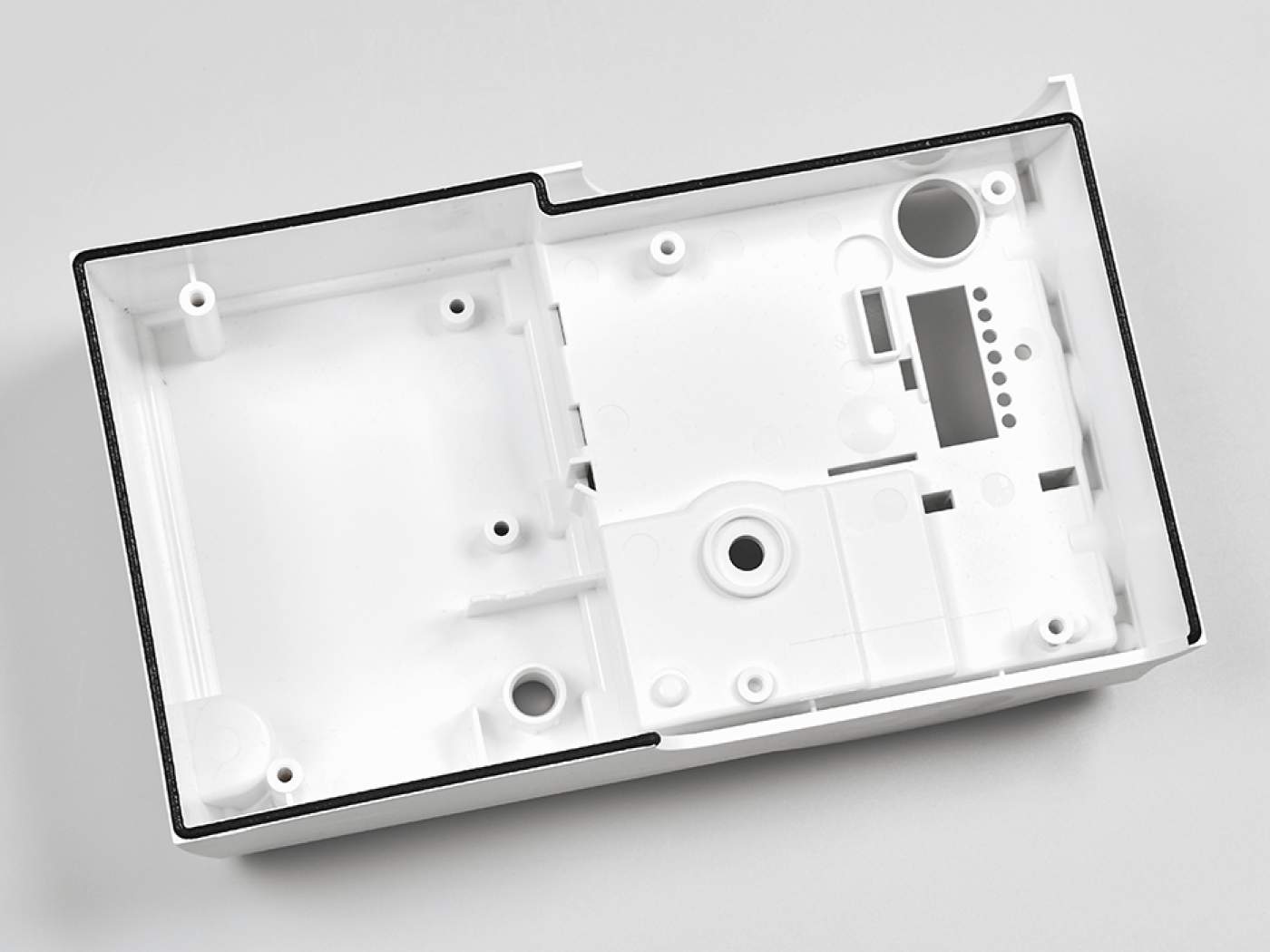

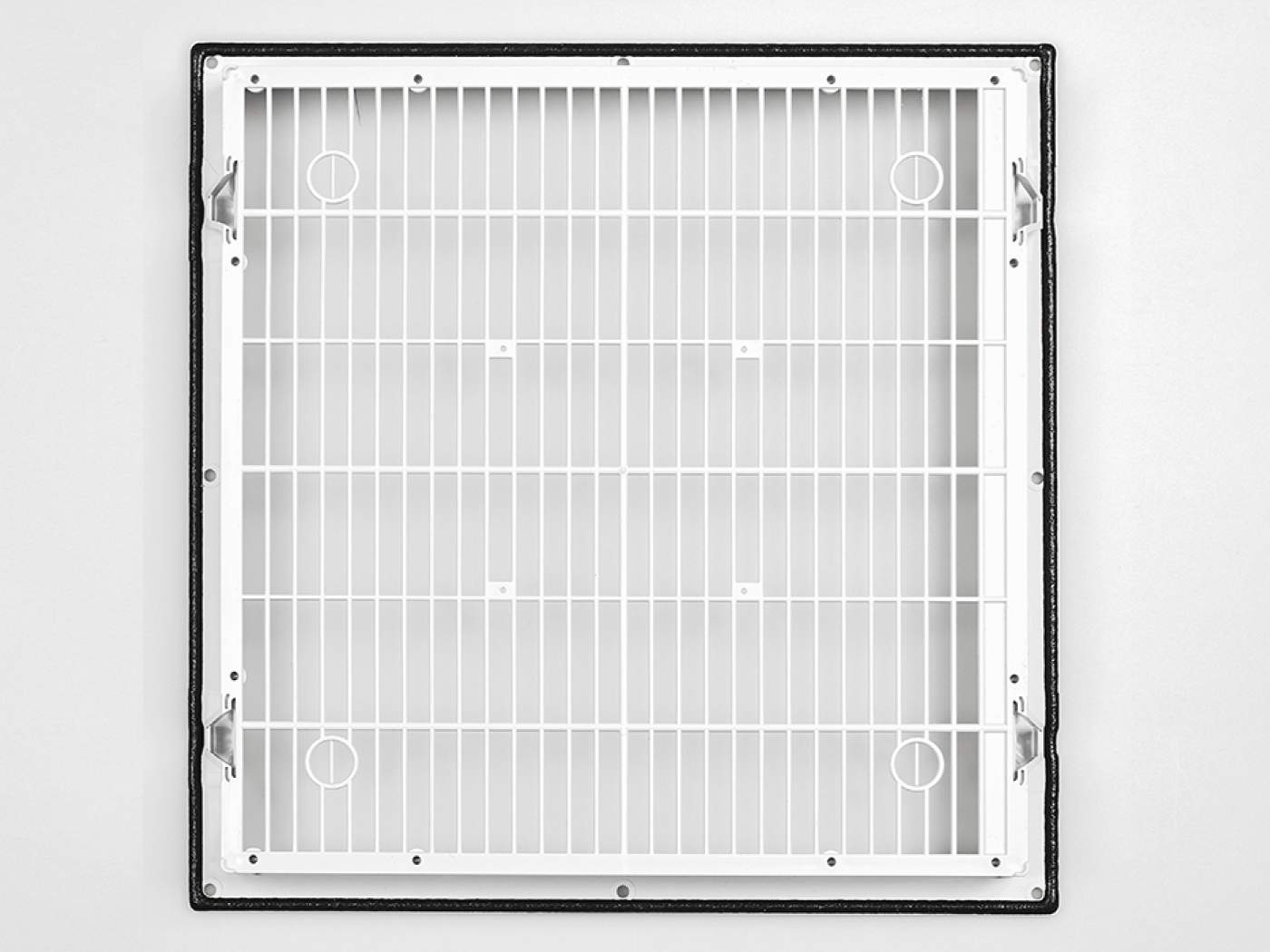

Our latest innovation is the pioneering 1K foam technology that we have integrated into our production. This means that we can now apply the sealing material to your components with pinpoint accuracy. The type of material is almost irrelevant.

The biggest challenge for a sealing system is protection against moisture and wetness. Previously, this could be achieved by manually inserting sealing cords or punched gaskets. Later, automatically applied sealing systems were developed on the basis of two-component technology.

Today, single-component foam gasket technology is state of the art. Unlike two-component foams, the innovative, closed-cell Penguin Foam® from SUNSTAR remains tight even if the surface of the foam has been damaged.

The closed-cell foam can do even more: Not only moisture and wetness, but also dust and dirt are kept out thanks to the innovative technology.

Innovative foam material

The innovative foam material offers a wide range of applications. It can be used not only as a seal, but also as a "buffer". Components of different material hardnesses meet in the vehicle interior, for example. While driving, they absorb the resulting dynamic movement. This results in friction noises. This is noticeable in the form of creaking center consoles, rattling glove compartment lids or squeaking seat belt covers. To prevent this, the single-component Penguin Foam® from SUNSTAR is applied to the relevant components. It acts as a compressible buffer and effectively and permanently prevents unwanted noise.

Our flexible production equipment is cost-effective and can be precisely tailored to your tasks. This is possible for prototyping as well as for later series production. With our robot system and our Foamply-E® foaming system, we can also apply small and complex sealing geometries perfectly and with high precision to your assemblies.

These seals made from single-component elastomers are dispensed in liquid form directly onto the component to be sealed. This has a whole range of advantages:

- high resilience

- compressible

- low surface pressure

- Compensation of housing tolerances

- UV resistance

- media resistance

- free of silicone

- soft elastic with adjustable softness

- suitable for electrical applications

- no paint wetting problems

- temperature resistant up to 80 °C and briefly up to 100 °C

- closed-pore

- compression max. 70 %

- water absorption less than 10 % (with 2K systems up to approx. 100 - 150 %)

The material

Penguin Foam® 3151 E is a one-component polyurethane elastomer that is heat-curing and solvent-free. It was specially developed for the rational and environmentally friendly application of foamed seals.

The material is mechanically foamed using a Foamply-E® foaming system. This creates a soft, elastic, closed-cell foam seal.

The best cross-linking reaction begins at 80 °C. It only takes a few minutes. The material is particularly suitable for applying seals to plastic parts. Even wood, paper and all metals are possible!