Not just plastic - our wide range of injection-molded parts

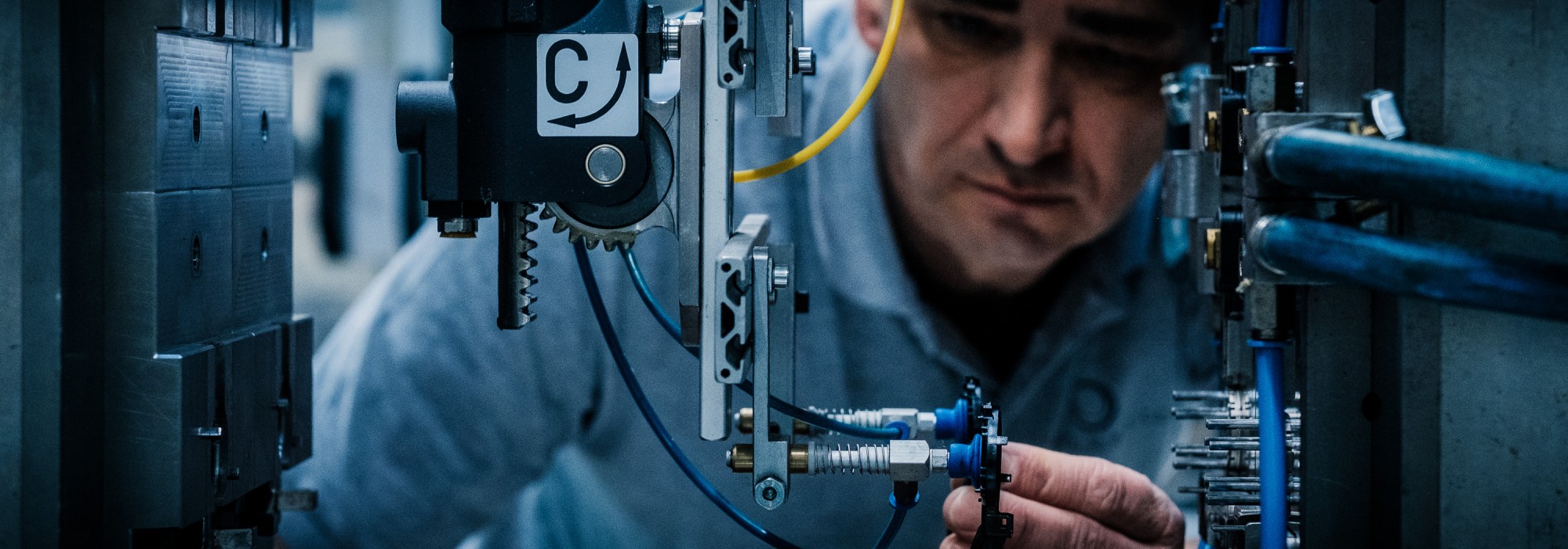

One of our core competencies is injection molding. Our production is designed for the manufacture of small and medium series as well as for large series production in multi-shift operation. Our state-of-the-art machinery includes 110 technologically advanced injection molding machines with a clamping force of 150 kN to 3,500 kN.

Our range of services includes injection molded parts weighing from 0.1 g to 1,000 g made from all common thermoplastics. We have extensive expertise in the field of engineering plastics, including polyamides, polycarbonate, numerous different TPEs and polyethersulfone.

We process highly heat-resistant plastics on our high-performance vertical machines. In order to guarantee quality for the highest demands, process monitoring is software-supported.