Tradition, consistency, experience –

Put your trust in our know-how.

Kai Plastics GmbH & Co. KG has three locations that are characterized by their specific competencies. In this way, strengths are pooled where they are needed. Synergies in purchasing, technology and sales are exploited. Production is specialized at the individual locations. Short decision-making processes and the independence of the individual locations allow for a high degree of flexibility. We develop, manufacture and supply injection molds, assemblies and technical plastic parts for almost all industries worldwide. We guarantee the highest precision. We accompany the entire process as a competent development partner, from the initial concept to tool design, selection of materials and surfaces, right through to cost-optimized design and manufacture of the products.

Guarantors of the highest quality

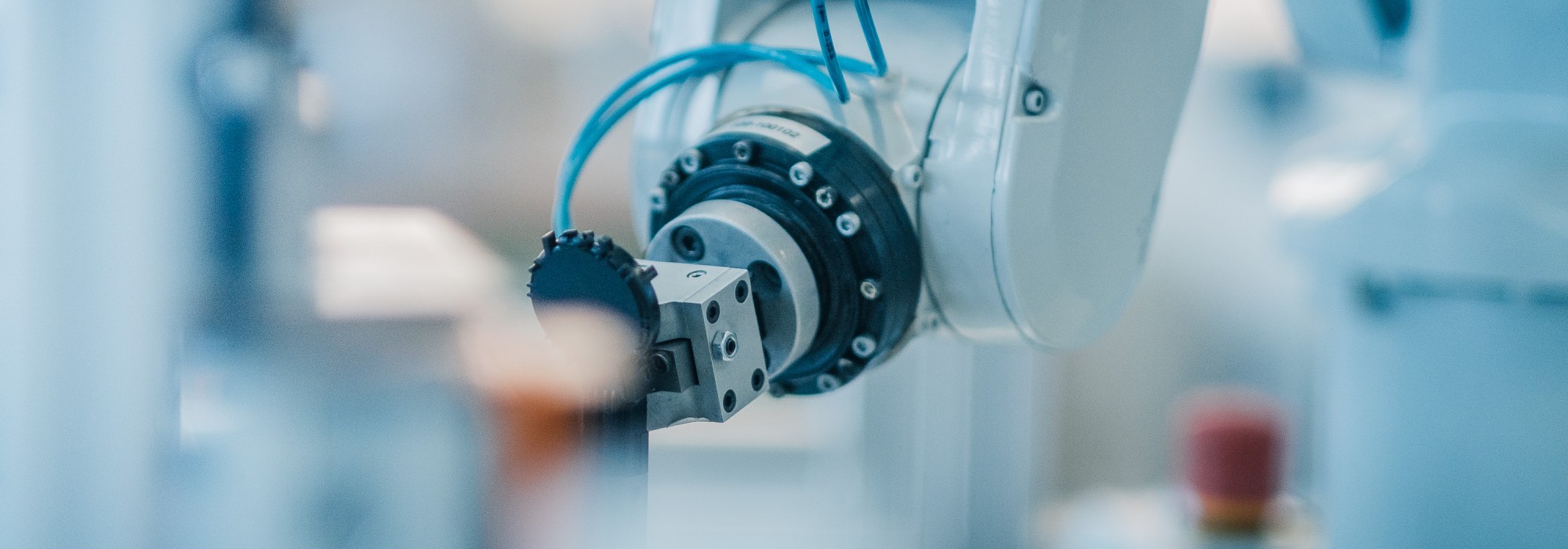

Components with an injection weight of 0.1 g to 1,000 g are produced in small and large series on 110 state-of-the-art injection molding machines with a clamping force of 15 t to 350 t as well as with injection molding automation using robots. Particularly flexible production is ensured by working in 2- and 3-shift systems. Our decades of expertise in production and tool technology and our high level of vertical integration guarantee the highest quality, cost-effectiveness and sustainability. To ensure that we remain competitive in the future, our philosophy is characterized by training, personnel development, willingness to invest and customer orientation.

Our latest innovation is the pioneering 1K foam technology for the precise application of sealing material to your components. The finishing of the products, which we carry out according to customer requirements, is becoming increasingly important. We pay particular attention to printing with screen printing and pad printing.

All services from a single source

Our extensive experience in project management and in the development of assembly machines, our own tool design, our toolmaking and our injection molding services enable us to support the entire value chain, from planning through to series production or the manufacture of complex systems. You receive all services from a single source - from us as a competent partner for all your projects.

Our strong alliance, the industrial holding company Kai Capital in Neuss, guarantees economic and financial strength. Production is optimized in every respect. Reboplastic GmbH is an important partner. It specializes in the production of high-quality packaging solutions and linings. Thanks to our cooperation with Reboplastic, we can supply high-quality thermoformed parts from a single source. You can rely on fast and unbureaucratic processing by a single point of contact and on our expertise.